TARPAULIN

MULTI PURPOSES TARPAULIN PVC COATED FABRIC

Through the years, a tent design and purpose keeps evolving to adapt human needs of outdoor activities such as sheltering, camping, party or even a warehouse. This history records shows that not only the designs and purposes evolves, but the material evolves and adapts to the human needs.

Being fully aware of such a need, Ateja through its international brand AGTex releases a revolutionary Multi-Purpose Tarpaulin PVC Coated Fabric that can be used for various needs such as tents, inflatable toys, truck cover & side curtain, and so on.

With the latest technologies that we have implemented, various treatments that enables the material to be fire retardant, anti molding and to be UV resistant can be added per your request.

Truck Covers & Side Curtain

Marquee Tent

Clear Span Tent

Inflatable Toys

TECHNICAL SPECIFICATION

The technical specification shown here are based on the best current available and average results from laboratory testing with at ±5% tolerance and provided as a source of information only and do not constitute any agreement concerning the good's warranty and refers to the goods supplied on original state without any processing done by the customer.

The specification suggested here does not guarantee the particular application of the customer and it requires the customer to conduct their won comprehensive test concerning suitability of the material for its intended application.

*** Available in 550ACB, 600ACM, 630ACB, 650ACM, 670ACM, 720ACC, 900ACI.

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 550 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.45 mm |

| Tensile Strength | : | 260 daN/5cm |

| Tear Strength | : | 25 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 9 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 600 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.48 mm |

| Tensile Strength | : | 280 daN/5cm |

| Tear Strength | : | 28 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 9 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 630 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.5 mm |

| Tensile Strength | : | 260 daN/5cm |

| Tear Strength | : | 25 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 9 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 650 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.5 mm |

| Tensile Strength | : | 280 daN/5cm |

| Tear Strength | : | 28 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 9.5 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 670 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.52 mm |

| Tensile Strength | : | 280 daN/5cm |

| Tear Strength | : | 28 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 9.5 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 720 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.55 mm |

| Tensile Strength | : | 300 daN/5cm |

| Tear Strength | : | 30 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 10 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

| Coating Material | : | PVC (Polyvinyl Chloride) |

| Base Fabric | : | High Tenacity Polyester |

| Total Weight | : | 900 gr/m2 |

| Width | : | 200 cm, 250 cm, 300 cm, & as requested |

| Thickness | : | 0.73 mm |

| Tensile Strength | : | 400 daN/5cm |

| Tear Strength | : | 55 daN |

| Working Temperature | : | -30 ∼ +70 oC |

| Flame Retardancy | : | Available upon request |

| Adhesion | : | 12 daN/5cm |

| Finishing | : | Glossy/Matte |

| Quality Management System | : | ISO 9001:2008 |

| Standard EN ISO 2286-2 | : | Total Weight & Thickness |

| Standard EN ISO 1421 | : | Tensile Strength |

| Standard EN ISO 2411 | : | Adhesion |

| Standard DIN 53363 | : | Tear Strength |

DOWNLOAD CATALOGUE

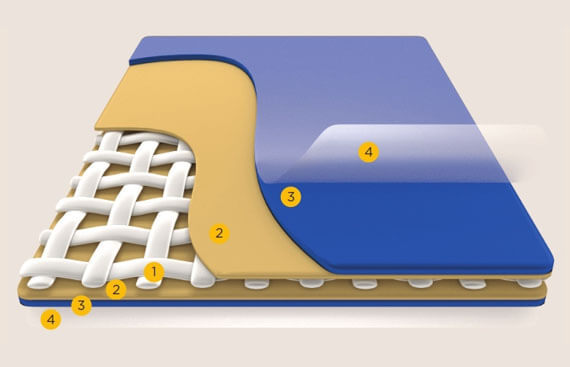

COMPOSITE MEMBRANE

1. Base Fabrics

2. Primary Coating

3. Top Coating

4. Surface Treatment (Lacquering)

BASE FABRIC

A woven base fabric of high tenacity polyester yarns is the base material to provide tear strength, tensile strength and dimensional stability on finished product.

PRIMARY & TOP COATING

The primary PVC coating impregnate the base cloth to enhance the impressive dimensional stability, high tensile strength and high elongation rupture.

SURFACE TREATMENT (LACQUERING)

Applying the lacquer on the surface generates the maximum protection quality against atmospheric chemical, microbial and fungal attacks, weather and environment friendly resistance to Ultra Violet Thermal, Rain, Abrasion and Flame Retardant.

THE MAJOR ADVANTAGES

- Limitless architectural design possibility

- Low construction cost & efficiency

- Available for large size roofings & fitting

- Lightweight and flexible yet strong and durable

- Easy handling and fast installation

- Mobile, temporary and permanent basis use

- Weather and environmental friendly

MAIN BENEFITS

- Easy Maintenance

- Waterproof

- Cost Efficiency & Light Weight

- Longetivity